Features

Introduction

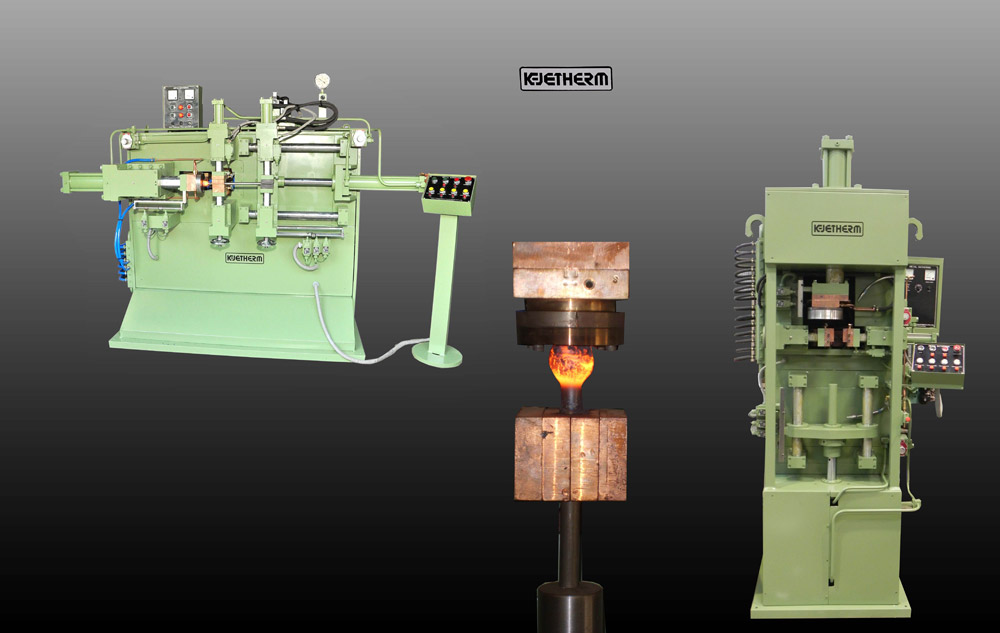

Kejetherm Metal Gathering Machine is fully hydraulically operated with Resistance Heater.

Principle of Operation

Metal Gathering operation consists of heating the part of the job and pushing the remaining cold material of the job into hot zone till the required metal gathering takes place.

Advantages

By employing Metal gathering many of the well known technical limitations and disadvantages of mechnical upsetting can be overcomed.

- Simultaneous heating and forming in one machine.

- Almost unlimited gather in one operation. The mechanical upsetting limitation of about 3 x dia. no longer applies. The modern engine valve has an upset length of up to 20 x dia. and lengths of upto 40 x dia. are commonly electro-upset.

- No longitudinal flash is formed such as is unavoidable in a split-die mechanical upsettler.

- No waste of heating energy or material. Outside of the upset volume can be precisely controlled to allow subsequent, "flashless" forging in closed dies.

- Always ready for instant use, no warm up period.

- Energy efficient, about 0.35 - 0.40 kwh / kg.

- Minimal scaling because of simultaneous heating and gathering. Improved die life in subsequent forging operations.

- No environmental pollution by emission of heat, fume or exhaust gas.

- Free upsets can be finished forged without re-heating and so save time and energy.

- Consistant heating temperature through the use of thyristor control.

- Optimal grainflow and fault free surface. The unheated bar length remains unchanged.

Technical Information of Metal Gathering Machine

| MODEL | TMG/V-25 | TMG/V-50 | TMG/H-50 | TMG/H-100 | |

| Heat Rating of Machine | KVA | 25 | 50 | 100 | |

| Bar range optimum from to | mm | 9-18 | 12-24 | 20-40 | |

| Normal Bar length clamped | mm | 6 | 10 | 12 | |

| Maximum upsetting strok | mm | 150 | 200 | 300 | 500 |

| Maximum upsetting cylinder force | tons | 3 | 8 | 12 | |

Application

Typical Electro-upset Parts Rear axle shaft

Drive shaft or torsion bar

Engine valve

Pinion gear

Tie-rod end

Selector fork